In the rush to prepare medical workers for the peak of the coronavirus curve, researchers on the NYU COVID-19 Task Force are working to design and supply face shields to medical workers.

The NYU COVID-19 Task Force is made up of faculty from across schools, including Tandon School of Engineering, the College of Global Public Health and NYU Langone Health to respond to COVID-19. The goal of the Task Force is to create a network of coronavirus-related projects across NYU to catalyze relief efforts, whether through connecting researchers or suggesting city organizations with which to coordinate. The Task Force’s first mission has been providing medical workers with personal protection equipment.

“The Task Force is part of addressing the problem of how you can bring in the university to try to identify problems that can be solved in the short term,” managing director of Future Labs and Task Force leader Steven Kuyan said. “Our mantra is asking what the pathway of least resistance is to building really necessary solutions to problems that the healthcare industry is facing.”

NYU Tandon Future Labs’ mission is to hone tech entrepreneurs to create successful businesses. Kuyan and lab leaders are using this commercial mindset to connect researchers at NYU Tandon with local manufacturers, health experts at NYU Langone and city offices.

The shields are made to be manufactured quickly, shipped efficiently and used almost immediately upon arriving at hospitals. While considering which tools to use to create the shields, the Task Force kept these goals in mind.

“There’s a couple of facial shields designed that require 3D printing,” Kuyan said. “That is far too long of a process to manufacture face shields at the numbers that they’re needed. New York City, for example, needs in the millions of face shields and on average 3D printing will take roughly two and a half hours to print the face shield.”

Many design options were drafted and went through experts at NYU Langone and NYU School of Global Public Health for feedback and approval. Once finalized, the design was made publicly available through the Open Face PPE project and has received feedback from across the country and internationally. The design is being used as far away as Germany.

“Our communication around folks who are producing this, you know, whether it’s in their ecosystem, whether they’ve made improvements or iterations of the design and they sent it to us and we updated our designs if necessary,” Kuyan said.

The Task Force is working with three New York City manufacturers to adapt their process to the production of face shields and start supplying the city.

“We help them think through whether or not it makes sense to assemble them, what alternative materials might be,” Kuyan said. “In some cases, they send samples to validate them before working with the city and then we connect them to the city directly so they can get a procurement contract with the city.”

The first round of shield production began the week of Monday, March 30. Close to 300,000 shields will be produced over the two weeks after materials are delivered to production sites. The production is funded by a $2 million grant from the New York City Economic Development Corporation.

A key resource for the Task Force has been NYU MakerSpaces — areas equipped with 3D printers and laser cutters for students and researchers alike — located at NYU Tandon’s main campus and at the Future Lab. In these spaces, Task Force members move through various designs to create the finalized version.

In addition to providing a testing space for the COVID-19 Task Force shield design, NYU Tandon’s MakerSpace team has created a shield of their own. The MakerSpace team’s design is slightly more complex and requires laser cutters and 3D printers, which means it cannot be manufactured on a large scale in the same way the Task Force’s design will be.

Twenty 3D printers and two laser cutters are being wielded to manufacture the MakerSpace shields. At least 500 have been assembled and distributed to New York City hospitals by volunteers, director of MakerSpace Victoria Bill said. The benefit of this second design is that volunteers are able to manufacture and distribute the shields immediately.

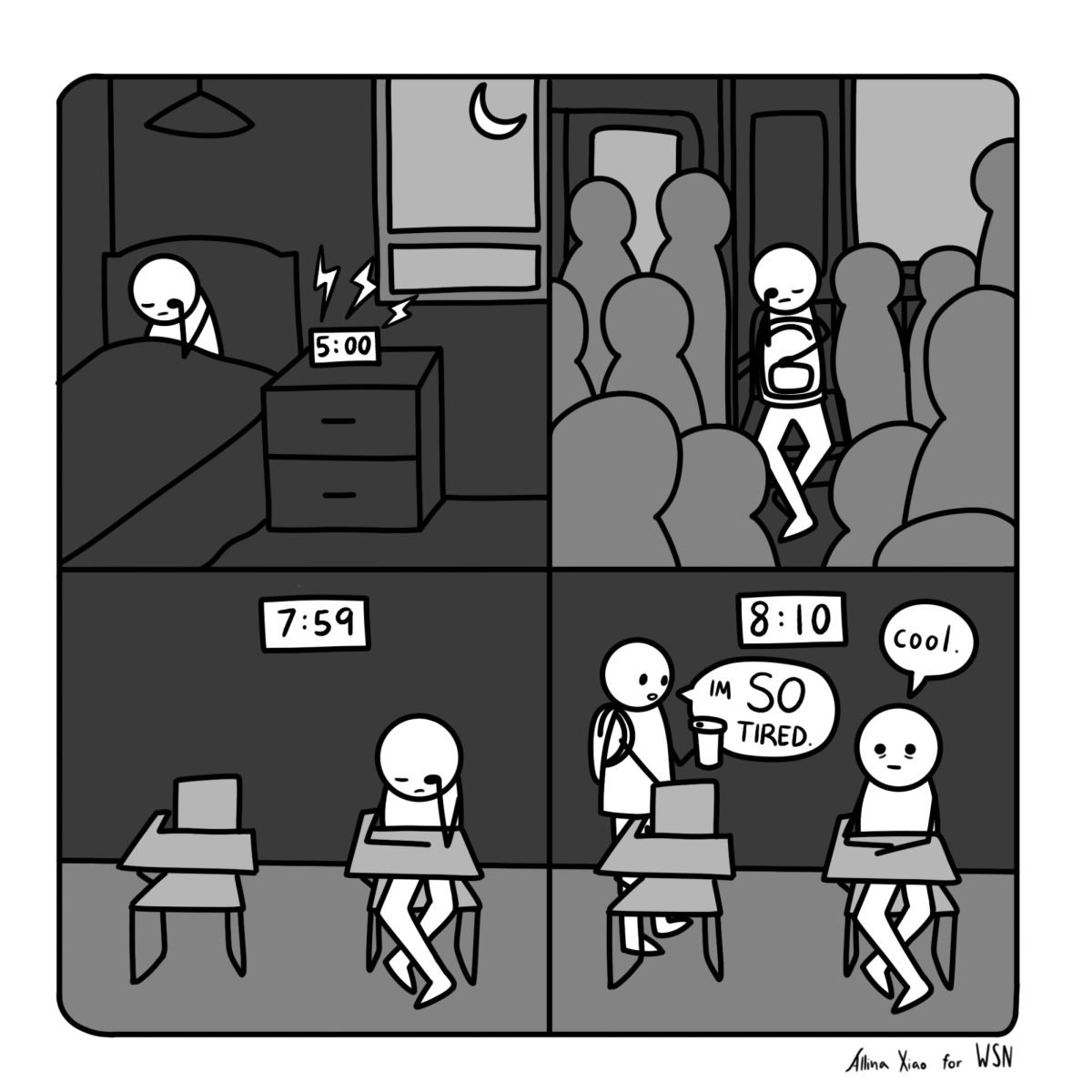

“Before manufacturing and the defense production acts can really ramp up — those things take a little bit of time to kind of come up to full speed — there is a very large immediate need,” Bill said. “So I think really the past two weeks and I think maybe the next two weeks is when we’ll be able to have the largest impact and when our services will really be needed.”

This sort of collaboration across teams and schools within NYU is a key goal of the Task Force, Kuyan said.

“We really wanted to identify everyone at the university who’s working on anything COVID-19 related that we can either help support and they’ll catalyze if it’s a product, how can we help bring it to market?” he asked. “Just so we can try to try to support everything that’s happening on campus.”

A version of this article appeared in the Monday, April 6, 2020, e-print edition. Email Emily Mason at [email protected].