Tandon School of Engineering researchers are hoping to bring together a team with lofty goals, like repairing U.S. infrastructure and building bases on the Moon, or even Mars. It will be one that is smarter, more efficient and better than any past teams because, well, they’re robots.

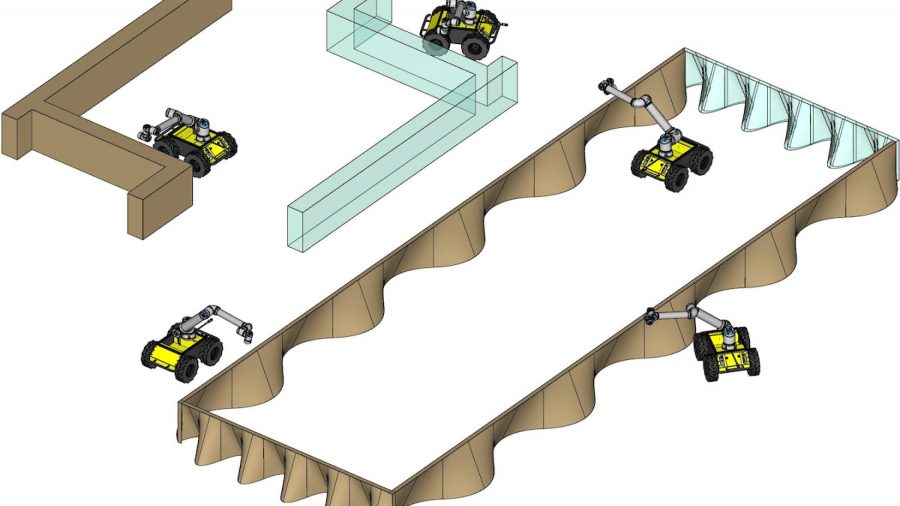

A group of interdisciplinary robotics experts at Tandon School of Engineering has received a $1.2 million grant to develop autonomous robots equipped with 3D printers that will work in teams to repair and build new structures.

3D printing starts by designing a three-dimensional object in a computer program. The 3D printer then takes that file and prints micro-thin layer by micro-thin layer of the object over the course of many hours, in a process known as additive manufacturing. The objects are generally small and made of plastic, and are often used when prototyping new devices.

The problem that the researchers are aiming to tackle is that current 3D printers are immobile, meaning that the objects need to be printed within the printer itself. One current approach is to print the parts of a larger structure, such as a bridge, in a factory with large 3D printers, and then assemble it on-site.

The researchers hope that by attaching 3D printers to the arms of robots, each about a meter in length, an entire structure can be built on-site instead. The robots will be autonomous and work in teams, splitting up the work of building the structure without human intervention.

“We believe there’s more room to improve,” said Weihua Jin, Industry Professor of Civil and Urban Engineering and a research team member. “And that there are a lot of opportunities for us to use additive manufacturing to revolutionize the way we [build things], how we build things and repair things.”

Assistant Professor of Civil and Urban Engineering Chen Feng is focusing on the robots’ awareness of their surroundings, while Professor of Mechanical and Aerospace Engineering Maurizio Porfiri is working on coordinating the actions of the robots to work in unison.

Associate Professor of Electrical and Computer Engineering Ludovic Righetti is developing algorithms to allow the robots to adapt to their environment.

“The robots will be able to basically understand where they are in the environment, see what infrastructure that they are building and decide how they need to print things,” Righetti said. “And the idea is to have everything done without human intervention.”

The project is expected to take at least three years and will be developed in three phases. In the first phase, the team will work on developing the algorithms required and modeling the actions of the robots in simulations. In the second phase, they’ll create an indoor testing ground to build prototype structures, such as a model of The Brooklyn Bridge. In the third phase, they aim to build a larger structure outside, mimicking a real-world construction environment. Eventually, the team hopes the robots could be used in large construction work across the U.S., building infrastructure like bridges and tunnels.

Feng said that he hopes the robots will one day be used to build bases on the Moon or Mars.

“It is quite difficult to imagine that we’re going to build a big gantry there, and then start to use 3D printer[s],” Feng said. “It is more realistic to think about vehicles like the Mars Rover, which also [has] the ability to make static bases using the materials on-site.”

Gallatin senior Aaron Hoffer, who has prototyped objects using 3D printers for several years, said he thinks their idea makes sense.

“Since sending humans to space is expensive and dangerous, sending a robot to automatically create a structure for you would be pretty handy,” Hoffer said.

Part of the researchers’ goal is for the robots to build structures that are either hard or unsafe for humans to do themselves. Righetti added that he believes robots taking over the manual labor humans do would be beneficial.

“[If] these robots are used in a way that can make people not have to work anymore, I think that would be wonderful,” Righetti said. “If people just work 10, 12 hours a week and could still have a very reasonable life.”

SPS junior Franklin Reitzas, who’s worked at the Prototyping Lab at the Leslie eLab for several years and leads tutorials on 3D printing, said he was optimistic about the researchers’ goals.

“What the professors are doing right now, that’s a new, crazy idea,” Reitzas said. “But of course, crazy ideas are the ones that are the most successful.”

Email Akiva Thalheim at [email protected].