Tandon Students Help Design Hyperloop at SpaceX Headquarters

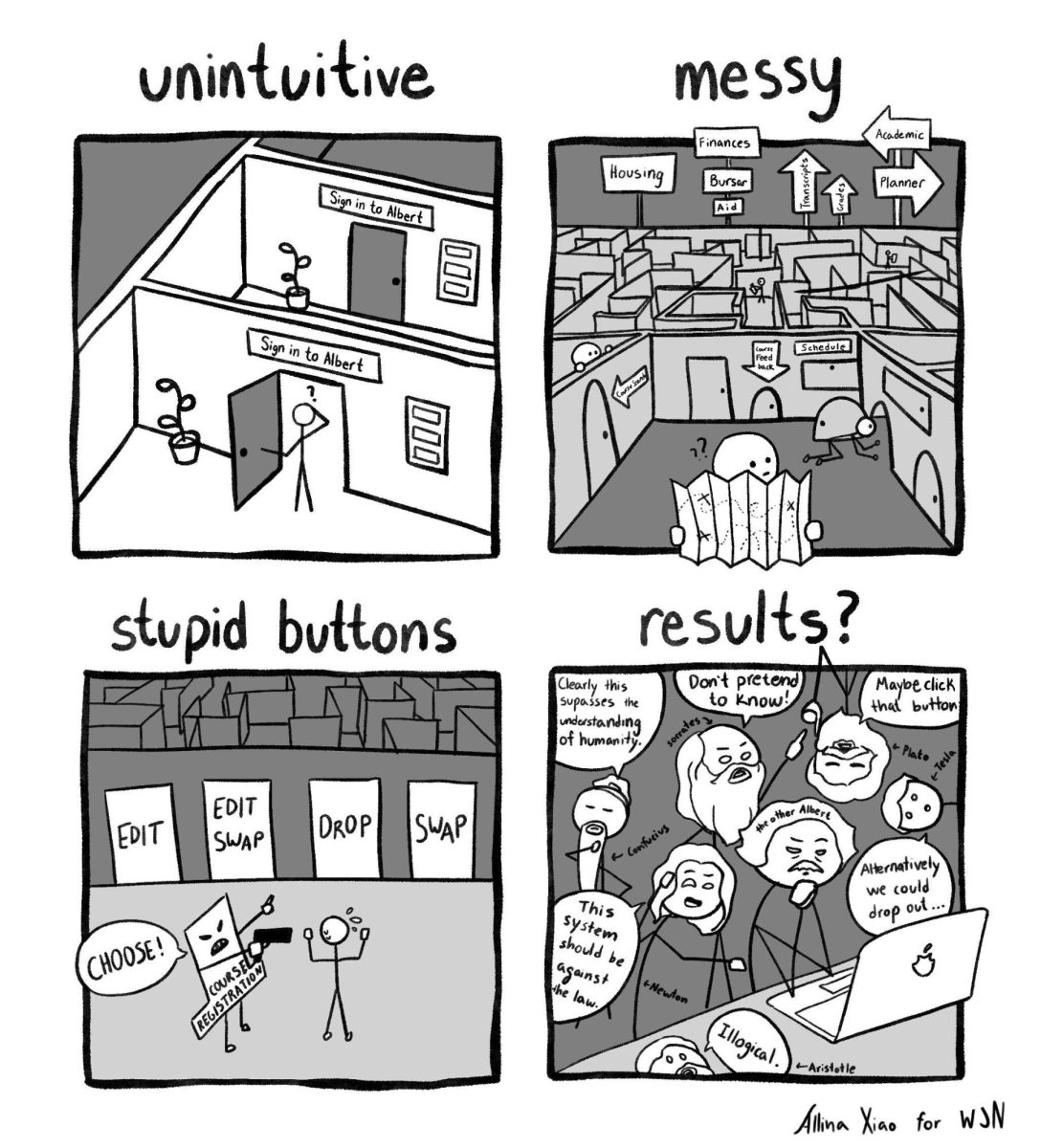

A digital rendering of the hyperloop system to be established at NYU Shanghai. The project has been run by a team from NYU’s Tandon School of Engineering.

February 16, 2017

Starting with sketchpads and ending at the SpaceX Headquarters, the team of Tandon students that designed a pod for the new Hyperloop One finally constructed their project after a year and a half of working and waiting.

The Hyperloop is a conceptual transportation system proposed by Elon Musk, the founder and CEO of SpaceX and Tesla Motors. The system allows a pod-like vehicle to travel in a vacuum sealed tube to improve efficiency and lower energy consumption. To accelerate the development of functional prototypes and to encourage student innovation, SpaceX launched its Hyperloop Pod Competition, a series of design and on-track tests spanning from January 2016 to summer 2017.

The Tandon team’s success in the 2016 design portion of the competition qualified them for the Competition Weekend at the end of January. The Tandon Hyperloop team and 28 others tested their pods in the real tube track outside of the SpaceX headquarters in Hawthorne, CA.

Tandon alum Ben High is the captain of Tandon’s Hyperloop team, and he said that despite qualifying for this leg of the competition, the team had to do a lot of work at the competition before they could run the pod in the tube.

“The competition lasted about seven to eight days, during six of which our team did setup and basic tests,” High said. “SpaceX blocked out all the traffic and built a one-mile Hyperloop tube on a public road permanently. To run the pod in the tube, we had to get the SpaceX engineers’ approval by fulfilling all 30 to 40 requirements on the checklist.”

Tandon junior Kashish Garg, the pneumatics lead engineer, said that Tandon’s team has been successful so far because of its focus on freight transportation while designing and engineering.

“When people hear about Hyperloop — you’re going to be in a pod inside of a tube shot at 700 miles per hour — they are not ready to do that on their own,” Garg said. “So we came up with this freight transportation idea that for two or three years we’ll send shipping containers for different companies with the hyperloop itself, and hopefully we can gain the public’s trust to let people believe that it’s a [form of transportation] that has the speed of the plane and the convenience of the train.”

Although the team wasn’t able to finish the pod test due to time and resource limitations, High said the team was happy about the successful vacuum chamber test — the toughest test that proves the systems can work in low-pressure environments.

“It’s the first time SpaceX has ever hosted a big competition, so they didn’t have enough time or resources to get every team as far as it expected,” High said. “In the end, only three teams had time to do full-scale tests and even the top team was only able to go at a third of the speed they wanted us to go.”

While unable to compete due to the logistical oversight, High said that the team will attend the next competition in summer 2017. To prepare for the next round, High said their focus now is to improve designs and mechanics as a whole.

“We saved money, resources and time by only building the part of the pod that is necessary to get into the vacuum chamber,” High said. “But next time we’re going to build everything, including wheels, chassis, suspension and lateral stability. When we’re confident enough that all the test requirements are fulfilled, we’re trying to do a full run at 150 mph in summer.”

Tandon senior Dmytro Moyseyev serves as the power electronics lead of the team, and he was happy about the test result and confirmed invitation to the next round of the competition. But in addition to that, he was grateful of having a chance to look at the SpaceX headquarters.

“Going to the SpaceX facility was unforgettable — they literally build rockets,” Moyseyev said. “By talking to those engineers, I received so much inspiration and ideas that at this point I am bored in my classes. I cannot wait to get back in the lab to design and build things.”

Email Coco Wang at [email protected].